VpCI®-414 is a cleaner and degreaser that also removes temporary coatings such as Cosmoline™*, Cortec® VpCI®-368, VpCI®-388, VpCI®-389, and non-silicone-based waxes from metal and painted surfaces.

Description

VpCI®-414 is a cleaner and degreaser that also removes temporary coatings such as Cosmoline™*, Cortec® VpCI®-368, VpCI®-388, VpCI®-389, and non-silicone-based waxes from metal and painted surfaces.

FEATURES

• Heavy-duty temporary coating remover

• Good for light oils and greases

• Will not affect painted surfaces

• Non-flammable

• Mostly used at room temperature, thus reducing energy consumption. Can also be used in a heated bath for removal of heavy hydrocarbons.

• Viscous liquid that will cling to ceilings and vertical surfaces in a ready-to-use formulation

• Can be used effectively at low concentrations.

• Provides corrosion protection after parts have been cleaned

• Protects metal in solution and above the liquid line on carbon steel

• UFI: F7YX-N1DV-5U1Y-4RVU

*Cosmoline™ is a registered trademark of Houghton International, Inc.

TYPICAL PROPERTIES

Appearance: Clear light yellow liquid

pH: 10.9-11.4 (Neat)

Density: (SG) 8.6-8.7 lb/gal (1.03-1.05 kg/L)

Non-volatile Content: 18-25%

METALS PROTECTED

• Carbon Steel

• Stainless Steel

• Cast Iron

• Galvanized Steel

• Brass (<30% Zn)

• Copper

PACKAGING AND STORAGE

VpCI®-414 is available in 5 gallon (19 L) pails, 55 gallon (208 L) drums, liquid totes, and bulk.

To ensure best product performance, store in original packaging, indoors and out of direct sunlight at 40-100 F (4-38 C).

Shelf life: 2 years

VPCI®-414 DILUTION RATIO CHART

|

CLEANING APPLICATIONS

Removing coatings, non-silicone based waxes, greases, and other heavily soiled equipment:

1. Spray apply VpCI®-414

VpCI®-414 can be applied at full strength or diluted. It is best applied by spraying or immersion. The most ideal dilution,where one would get an adequate coverage of wet film for

vertical and under-hanging surfaces, is 40% water to 60% concentrate. VpCI®-414 can be sprayed with an airless or pump type sprayer, or used in a dip tank.

Let the product stand (wet) for 10-15 minutes, depending on the film thickness of the product to be removed and the length of time that the coating has cured. Reapplication may be required.

2. Removal of product and coating

The removal of the product and coating may be accomplished with a power washer at the following settings or even a common garden nozzle.

Pressure: 50-300 psi (3.4-21 bar)

Temperature: 115 ºF-160 ºF (46 ºC-71 ºC)

If coating removed is tacky or remains tacky in patches repeat step 1.

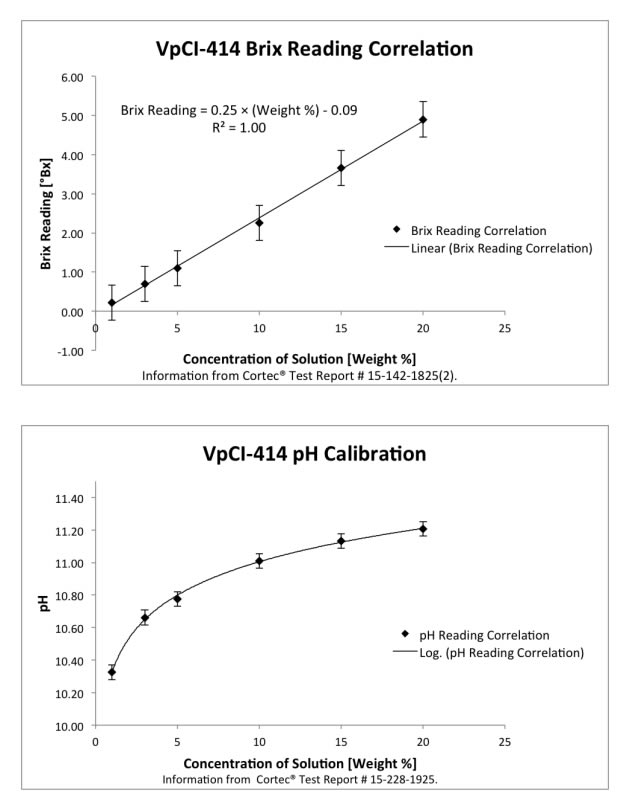

VPCI®-414 CALIBRATION CHARTS

Please note the solutions used above were created using deionized water. Slight differences in water chemistry (dissolved solids, hardness, etc.) may lead to differences in

readings. Please use these numbers as reference only: Contact DEYAP Laboratories with any questions..