Cor-Pak EX VpCI Film is made using high-density polyethylene and extruding with Vapor phase Corrosion Inhibitors (VpCI) to protect ferrous and most non-ferrous metals from corrosion. Simply wrap the metal object with Cor-Pak EX film. The VpCI in the film volatilizes and migrates with air then condenses on all metal surfaces, reaching all exposed and recessed areas.

Description

Cor-Pak EX VpCI Film provides a high level of corrosion inhibitor protection along with the excellent moisture barrier properties of high-density polyethylene film. It is unaffected by most solvents, strong acids, and alkalies. Incorporating Cortec’s proven Vapor phase Corrosion Inhibitors, Cor-Pak EX VpCI Film is the ideal solution when a combination of multimetal and mechanical protection is desired.

FEATURES

• Transparent

• Flexible

• Lightweight

• Strength & Conformability

• High Density Polyethylene Substrate

• Low Cost

BENEFITS

• Allows visual inspection without unwrapping

• Excellent for interleaving and wrapping

• Concentrated level of VpCI for maximum quick protection

• Priced to compete effectively with VpCI paper

• Easy-to-wrap product

Cor-Pak® EX VpCI® Film

• Low shipping costs

• Film will not tear or puncture when packaging oddly shaped parts

• Universal protection

• Protection against moisture superior to that offered by papers

• Reduces moisture and sulfur contamination found in VPI paper and corrugated containers

• Economical protection

• Extremely effective corrosion inhibitor protection

• Protects ferrous and most non-ferrous metals and alloys

• Environmentally friendly

• Good moisture barrier

• Recyclable

Metals Protected

• Carbon steel

• Galvanized steel

• Stainless steel

• Copper and alloys

• Aluminum and aluminum alloys

• Brass

• Zinc

ADDITIONAL BENEFITS

• Highest performing VpCIs made

• Vapor phase inhibition protects inaccessible and recessed surfaces

• If VpCI layer is disturbed by opening the package, protection is restored by closing the package

• Protected parts can be used immediately without degreasing or cleaning

• No spraying, wiping, dipping, or surface preparation of metal required

• Convertible to a wide variety of sizes of liners to protect small or large parts

THE APPLICATIONS

Cor-Pak EX VpCI Film provides corrosion protection to products, interleaved, wrapped, or shrouded. It represents excellent economical, and aesthetically pleasing replacements for VCI/VPI papers

ADDITIONAL APPLICATIONS

• Parts and components

• Tools

• Bin and box liners

• Electrical motors and mechanical controls

• Electrical and electronic assemblies and components

• Interleaving of coils and sheets

• Foam-in-place applications

• Bearings

• Interleaving of trays for parts storage/handling

METHOD OF APPLICATIONS

When using Cor-Pak EX VpCIfilm, metal items should be completely wrapped or shrouded to prevent the entry of moisture or air.

TYPICAL PROPERTIES

Form Extruded high-density polyethylene film

Appearance Transparent film

Thickness 1.0-1.25 mil (25-35 microns

EXAMPLE

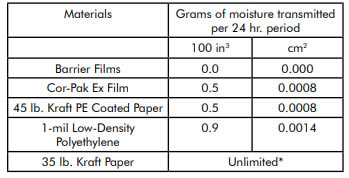

Barrier properties of various packaging materials

MECHANICAL PROPERTIES

*Typical Properties represent average laboratory values and are not intended as specifications but as guides only