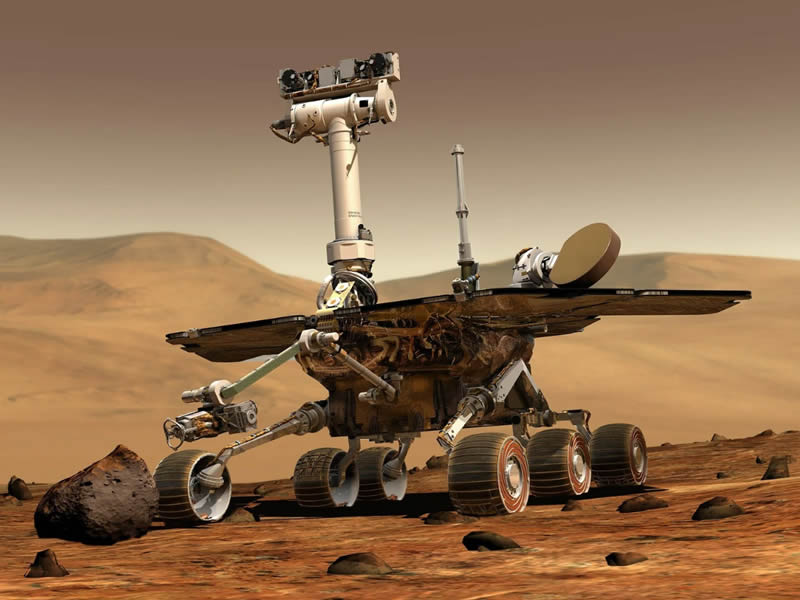

NATO planes are being held in the hangar for the next operation.

Aircraft, Aviation, and Aerospace Industries

Protection in the Aircraft IndustryDEYAP

Corrosion is a perennial problem in the aircraft industry, and preventing corrosion is a critical factor in maintaining the integrity and safety of an aircraft vehicle. Left undetected and untreated, aircraft corrosion can quickly lead to potentially catastrophic vehicle failure.

CAUSES OF CORROSION

Corrosion occurs when metal is exposed to oxygen and moisture. Corrosive chemicals or dissimilar metals can also initiate the corrosion process. Surface corrosion frequently occurs where metal is exposed or paint has worn thin. Stress corrosion is a common problem for aircraft under tensile stress in corrosive environments. Corrosion risks increase with aircraft age or exposure to extreme moisture and harsh environments.

CAUSES OF CORROSION

Corrosion occurs when metal is exposed to oxygen and moisture. Corrosive chemicals or dissimilar metals can also initiate the corrosion process. Surface corrosion frequently occurs where metal is exposed or paint has worn thin. Stress corrosion is a common problem for aircraft under tensile stress in corrosive environments. Corrosion risks increase with aircraft age or exposure to extreme moisture and harsh environments.

Aircraft, Aviation, and Aerospace Industries Protection MethodsDEYAP

Good corrosion preventive maintenance and early treatment are crucial strategies for protecting aircraft from corrosion failure. Keeping a vehicle clean with corrosion inhibiting washes and storage methods helps protect aircraft from corrosion attack during regular use and storage. Sometimes rust removal may be needed before applying additional corrosion inhibitors, such as VpCI® primers and coatings, to an aircraft. With Cortec® Vapor phase Corrosion Inhibitors (VpCIs) it is possible to slow the attack of corrosion on aircraft from multiple angles.

Aircraft, Aviation, and Aerospace Industries

CORTEC® ADVANCED TECHOLOGYDEYAP

Cortec® has developed technology to fit the ever-increasing demands for better corrosion control measures in the aviation industry.

Thanks to the development of new technologies and the committed work of our scientists and engineers we are able to use the most innovative advanced corrosion protection method available today - the application of VpCI®.

This is a safe, cost-effective method for preventing severe damage caused by corrosive processes in the aircraft industry. Cortec’s technology and products offer highly efficient and economical protection enabling our customers to effectively fight corrosion while decreasing their costs.

HOW CORTEC® CAN CUT COSTS?

Thanks to the development of new technologies and the committed work of our scientists and engineers we are able to use the most innovative advanced corrosion protection method available today - the application of VpCI®.

This is a safe, cost-effective method for preventing severe damage caused by corrosive processes in the aircraft industry. Cortec’s technology and products offer highly efficient and economical protection enabling our customers to effectively fight corrosion while decreasing their costs.

HOW CORTEC® CAN CUT COSTS?

DEYAP

All IndustriesDEYAP

Articles

Solved Cases from the PastDEYAP

Information page on how corrosion problems have been solved in various countries around the world.